Impact crushers, BMTA series

The Alquezar impact grinding mills work with new kinematics, achieving special advantages in crushing and in their economy.

The feedstock enters laterally into the primary chamber, where the impact bars knock it against the specific wedges, where it is crushed. The sharp edges of the impact wedges penetrate the material, exerting a high pressure and bending stress, which enables us to crush larger-sized rocks than existing models on the market. The fragments of crushed material reach the second grinding stage, whilst the large sized materials recirculate again towards the primary chamber. The precrushed material passes to the third stage where it is submitted to the final grinding.

The typical design of the primary impact chamber creates the first crushing stage together with the impact elements. In this first stage, the impact elements have sharp edges, to be able to penetrate the rock better, due to the stress concentration placed on it. This system leads to considerable energy saving and guarantees less wear of the plates, so the production costs are also reduced. The second and third stage impact plates are mounted on hydraulically adjustable supports, so that we can adjust their distance from the rotor, depending on the material to be processed and on the material we want to obtain.

The impact grinding mill housing is covered with cast iron plates, with bolt or wedge fastenings accessible from outside the machine.

The rotor shaft is made of high quality forged steel, calculated to support the greatest strain. The transmission pulley can be placed on both sides of the shaft. The rotor is made of very robust welded elements, with wear-proof welding in the peripheral areas submitted to greater abrasion.

Maintenance is quick and easy thanks to the hydraulic housing opening system, which permits access to the impact bars, impact plates and wedges of the primary, secondary and tertiary phases.

| Model |

Width (mm) |

Height (mm) |

Length (mm) |

Inlet (mm) |

Feedstock size (mm) |

Weight (kg) |

Power (C.V.) |

Production (t/h) |

|

| <2000 kp/cm2 | >2000 kp/cm2 | ||||||||

| BMTA-8.5.4 | 1.505 | 1.870 | 2.280 | 530×570 | 250 | 180 | 5.900 | 100 | 75 |

| BMTA-8.8.4 | 1.765 | 1.870 | 2.280 | 780×570 | 300 | 180 | 7.350 | 125 | 100 |

| BMTA-8.10.4 | 2.025 | 1.870 | 2.280 | 1.030×570 | 300 | 180 | 8.400 | 180 | 140 |

| BMTA-10.10.4 | 2.190 | 2.375 | 2.850 | 1.030×715 | 600 | 450 | 13.600 | 270 | 200 |

| BMTA-10.12.4 | 2.490 | 2.375 | 2.850 | 1.280×715 | 600 | 450 | 15.500 | 340 | 275 |

| BMTA-10.15.4 | 2.745 | 2.375 | 2.850 | 1.530×715 | 600 | 450 | 17.200 | 425 | 325 |

| BMTA-12.12.4 | 2.570 | 3.150 | 3.070 | 1.280×1.100 | 900 | 650 | 23.100 | 425 | 325 |

| BMTA-12.15.4 | 2.895 | 3.150 | 3.070 | 1.530×1.100 | 900 | 650 | 25.700 | 480 | 375 |

| BMTA-12.18.4 | 3.145 | 3.150 | 3.070 | 1.780×1.100 | 900 | 650 | 28.500 | 550 | 425 |

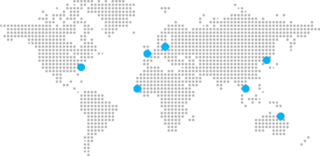

Main Location

Europe, Africa, Asia and America