Fixed dry mortar plants

The Talleres Alquezar dry mortar plants are bespoke installations, for stockpiling, mixing and dosing any type of dry mortars used for bricklaying and construction, offering installations that satisfy our customers’ most demanding requirements and specifications.

The Alquezar dry mortar plants are vertical. In the tower type mortar installations the aggregate is fed from a reception hopper and raised by bucket elevator. The aggregate is stockpiled in silos at the top of the plant together with the cement, so the discharge to the mixer is carried out by gravity. This is carried out quickly and without any mobile mechanical elements.

The horizontal shaft dry mortar mixers guarantee homogeneity of the mixture, thanks to the carefully designed mixing blade system.

The final product can be delivered in three different ways: in bags by means of an automatic bagging unit, unloaded directly onto lorry, or it can be stored in finished product silos for subsequent loading onto lorries.

Depending on the characteristics of the feedstock, the Alquezar dry mortar plants can be complemented with sand drying drums, to eliminate any humidity present, or tertiary crushing mills and classifying screen, which enable us to vary the granulometry and shape factor of the initial aggregate, to adapt it to the needs of the final product.

| Model | DMA-60 | DMA-100 | DMA-140 |

| Maximum production (t/h) | 60 | 100 | 140 |

| Cycle capacity (m3) | 1.7 | 2.3 | 3.3 |

| Typology | Tower plant | ||

| Aggregate elevation | Bucket elevator | ||

| Aggregate stockpiling | Upper silos | ||

| Cement stockpiling | Upper silos | ||

| Aggregate and cement weighing system | Independent scales | ||

| Direct unloading onto lorry | Standard | ||

| Automatic bagger | Optional | ||

| Finished product stockpiling silos | Optional | ||

| Sand dryer | Optional | ||

| Aggregate crusher | Optional | ||

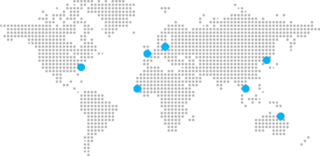

Main Location

Europe, Africa, Asia and America